We provide a comprehensive range of modern construction elements to create sustainable projects that adhere to environmental standards. This includes Elian bearing panels, which are made from expanded polystyrene and encased in double galvanized steel mesh connected by flexible, durable, and versatile connectors. These construction elements are manufactured as self-supporting panels in various shapes according to the project's engineering design, then transported to the site for the application of shotcrete and installation. This method offers a faster and more cost-effective solution compared to traditional construction methods.

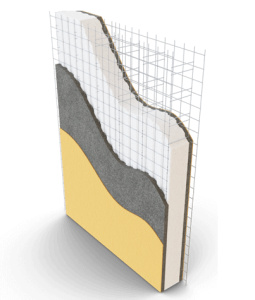

Single Panel

The Single Panel consists of expanded polystyrene encased in double galvanized steel wire mesh connected by connectors. It is then coated with two layers of shotcrete, with structural plaster applied to both sides.

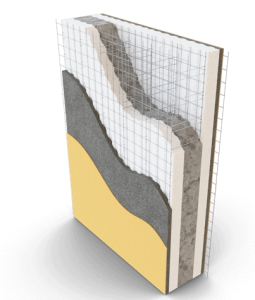

Double Panel

The Double Panel consists of two core panels made from expanded polystyrene, connected by double horizontal galvanized steel wires with connectors that create a hollow form. This form is then filled with reinforced concrete to meet project requirements. A layer of plaster is subsequently applied to the outer faces of the panels.

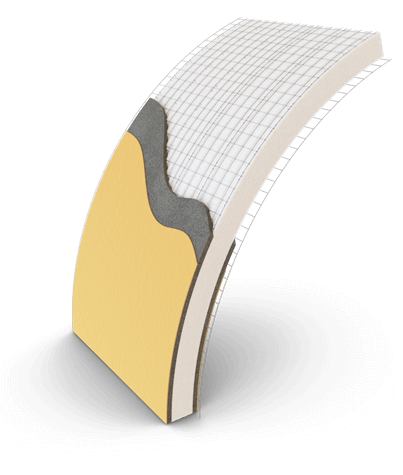

Curved Single Panel

The curved single Panel is a specially dimensioned panel produced flat in the factory and then arranged to form a curve. It is coated with two layers of shotcrete, with structural plaster applied to both sides.

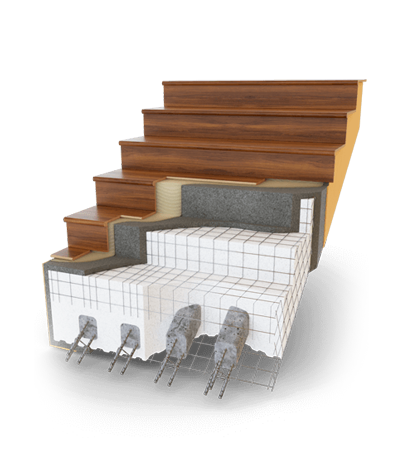

Stair Panel

The stair panel consists of a block of expanded polystyrene, designed according to the requirements to illustrate the connection between the upper and lower meshes. The stair is reinforced internally with steel and then cast with reinforced concrete. Finally, a layer of structural plaster is applied to the outer faces.

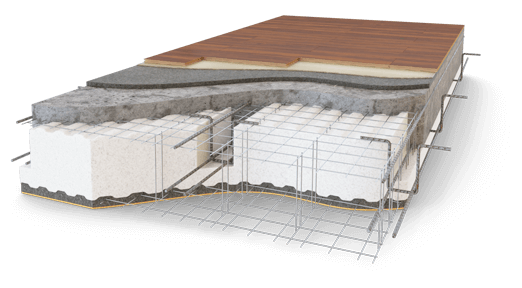

Half-Landing panel

The half-landing panel consists of expanded polystyrene ribs oriented in both directions according to the design requirements, illustrating the connection between the upper and lower meshes. A layer of structural plaster is then applied to the outer faces.

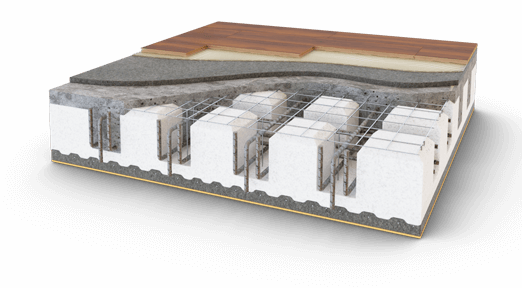

Ceiling Panel

The ceiling panel is designed for creating ceilings using expanded polystyrene, with the addition of specially arranged galvanized steel wires that illustrate the connection between the upper and lower meshes. This is followed by the casting of reinforced concrete. A layer of structural plaster is then applied to the outer faces.

Speed of Construction

Projects can be completed in a shorter period, making them 50% faster than traditional construction methods.

Low Cost

Our modern construction technology offers a cost reduction of 15-20% compared to traditional building methods.

Energy Efficiency

Our modern construction techniques provide more sustainable energy solutions by ensuring superior insulation for heating or cooling indoor spaces.

Environmentally Friendly

The raw materials used in the panels have a lower carbon footprint and help reduce environmental impacts while preserving natural resources.

Advanced Solutions

Alian panels utilize advanced technology to enable solutions for various projects using modern construction methods.

Quality

Alian panels are manufactured using the latest technologies in a single production and assembly line under highly controlled industrial conditions to ensure the highest standards of quality and efficiency.

| Key Features | Performance | Certification | Classification |

| Thermal Conductivity Coefficient (U) | 0.25 | SASO | Thermal Resistance |

| Gas Emissions Due to Heat | Resistant | SABIC | Thermal Resistance |

| Thickness (t) | 8 – 16 cm | SASO | Thermal Resistance |

| Denisty (D) | 15 -35 KG/m3 | ALIAN | Thermal Resistance |

| Compressive Strength at 10% Thickness of the Panel | 97.1 kilopascals | SASO | Pressure |

| Water Absorption | 0.6% | SASO | Water |

| Flexural Strength | 20.3 kilopascals | SASO | Buckling |